Or: Why you want a variable speed generator

This fall I spent a few weeks ‘back on the farm’ helping to bring in the crops. Along the way I had a chance to find a series of tractor tests conducted by the University of Nebraska documenting many performance measurements. Bar pull, speed / RPM, gear ratios, etc. Why is this interesting? Well, one of the things they documented is actual measured fuel consumption at different engine loads and RPMs.

A common rule of thumb for diesel engines is they will produce around 15-17HP for one hour while consuming about a gallon of diesel fuel. What is interesting from the Nebraska reports is this only holds true under full load at a given RPM. Example, take a look at this test data:

Source: http://digitalcommons.unl.edu/tractormuseumlit/1860?utm_source=digitalcommons.unl.edu%2Ftractormuseumlit%2F1860&utm_medium=PDF&utm_campaign=PDFCoverPages

What is interesting is at 100% load / max RPMS (115HP / 2100 RPM) the engine produced 17.4 HP*hr using 1 gallon of diesel. However, run that same engine under 25% load and the engine is around ½ as efficient – only able to produce a bit under 9 HP*hr from that same gallon of fuel.

What does this mean? Well, if you have a traditional fixed speed AC generator it is true it will consume less fuel under light loads – but it will be no were as efficient while doing so. Running that 7.5Kw generator at say a 2Kw load (charging up the house batteries) might be doing only ¼ the work, but its fuel consumption will only be reduced by ½ (not the ¼ we might hope for).

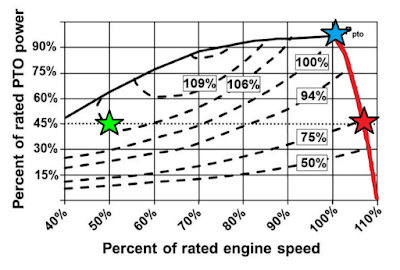

But there is an answer. Again from the Tractor World there is a concept of GUTD, or Gear Up Throttle Down. Meaning – if the load is light use a higher gear and pull back on the RPMs. Just like overdrive in a car, this can help recover most of the lost efficiency vs. running those loads at the higher (fixed) RPM. Again, here is an example from the Tractor world – this one from Virginia Tech:

Source: https://pubs.ext.vt.edu/442/442-450/442-450_pdf.pdf

This takes a little explanation: Start by looking at the blue star in the upper right hand corner. That point represents full RPMs and full engine load – and we see that the relative fuel ‘efficiency’ is 100%. However if we keep the same ‘throttle’ position but only apply say 45% of the load we drop down that red line on the right hand side to where it crosses the 45% load point (Red Star). Here we can see the 75% efficiency dashed line has been intercepted. This means if the engine produced 17HP*hr / gal @ 100% load, it will now only be 75% as efficient, and will now only produce 12.75HP*hr/gal. Bring the load down to the 30% point and we are again at ½ the efficiency as when under full load.

However what if the engine speed could be slowed down while under the light 45% load? Shift into Overdrive if you will. OK. See the Green Star? This is the same 45% loading (meaning we are producing the exact same Horse Power as when at the Red Star point) – but look; we have now intercepted the 106% efficiency curve! Meaning our engine will now produce 18HP*hr for each gallon of fuel consumed. Doing some math and coming up with a hypothetical example an engine using the representative graph might look like this:

Deliver 7.5Kw at full throttle burns 0.75 GPH

Deliver 3.3Kw at full throttle burns 0.45 GPH

Deliver 3.3Kw at half throttle burns 0.30 GPH

If we could reduce the engine speed to ½ we would save 0.15GPH in fuel.

Take this example to say a 2Kw load and the ‘savings’ will be even greater.

So what does this all mean? In short: run that fixed speed AC generator under a light load if just wasteful. Problem is most all AC generators run at a fixed speed, no matter how much of a load you put on them. It is the nature of needing to produce a stable 50 or 60Hz AC frequency. DC generators do not have that restriction and can be used at any RPM (just like the alternator in your car – and also some AC ‘inverter’ generators ala the small Honda’s). Being able to adjust an engines speed to match its load can pay off.

And here is where a DC generator with engine speed control can help. Just like this integrated engine speed controller does. In my quest to improve the efficiency of our DC generator looks like this is one significant factor that is already accomplished.

BTW: Here is another paper from Virginia Tech that goes into more detail, and even has some formulas for predicting engine performance at many different RPM and load points:

https://pubs.ext.vt.edu/442/442-073/442-073_pdf.pdf

No comments:

Post a Comment